A Next Generation of Subsea Production System for Deepwater Oil and Gas Development

by Menglan Duan, Chair of ISSC Subsea Technology Committee

Short Biography

Prof. Dr. of Solid Mechanics and Ocean Engineering, Director of Institute for Ocean Engineering of China University of Petroleum, Beijing, China.

Over 200 publications in high quality scientific journals.

Project Manager for over 150 Projects in Ocean Engineering, Mechanical Engineering and Petroleum Engineering.

Chairman of Subsea Technology Committee of the International Ships and Offshore Structures Congress (ISSC)

Chairman of China Branch of the Society for Underwater Technology (SUT)

Chairman of Industry-University Joint Committee of the Chinese Society of Theoretical and Applied Mechanics (CSTAM)

Visiting Professor at Federal University of Rio de Janeiro

Founding Editor-in-Chief of Frontiers in Fossil Fuel Engineering, Editor-in-Chief of Development and Application of Oceanic Engineering, and Editorial Board Members of 16 international journals

Member of the EU Academy of Sciences

Founding and Executive Chairman of the Annual SUT Technical Conference

Founding and Executive Chairman of the China-Brazil Deepwater Forum

The increase of oil and gas production has come from offshore fields in the globe in the past decade, and about 90% of the increase is from the deepwaters. Subsea production systems (SPS) including subsea pipelines and risers are the must equipment and facilities for the development of deepwater oil and gas fields. Their applications to deeper and remoter waters as well as arctic areas are challenging the scientists and engineers, especially in increasing safety and reliability. And, to reduce the CAPEX and OPEX of the deepwater fields by developing new technologies of subsea production systems is always the main concern of the industry. The technologies cover the whole period of life of the systems from initiation of concepts to design, manufacture, testing, transportation, installation, monitoring and inspection, maintenance, repair and decommissioning. Any technologies shall be all for the maximum oil and gas production, the minimum environmental impact, the minimum risk to assets and personnel, the maximum profit and the highest safety of the subsea systems, and their advances are progressing each year.

The subsea production systems cover all the equipment and installations below the sea surface of the ocean, including 1) subsea processing facilities like subsea X-trees, manifolds, valves, separators, boosting pumps, water or gas injectors, 2) power supplying units like electric distribution units, umbilicals, 3) transportation systems like subsea flowlines, jumpers, connectors, pipelines and risers, 4) subsea control systems and 5) subsea operation equipment and tools like ROVs for installation, inspection and monitoring, maintenance and repair, and decommissioning. The research of fields for innovation of such subsea production systems requires a very wide range of multi-principles of mechanical engineering, petroleum engineering, risk and safety engineering, electrical and control engineering, material sciences, theoretical and applied mechanics, and ocean engineering. The Offshore Oil/Gas Research Center of the China University of Petroleum has devoted its group for ten years to innovative development of the SPS and the application to deepwaters of South China Sea, and obtained around 100 patents as well as published over 200 technical papers. To further reduce the hazards and risks by improving the reliability of the SPS, and also to look for the possibility of greatly reducing the CAPEX and OPEX of the deepwater oil/gas fields, a new concept for next generation of SPS has been defined by Dr. Menglan Duan and got identically supported by the oil industries and universities from China, Brazil and Portugal. The main points of innovation could be presented like:

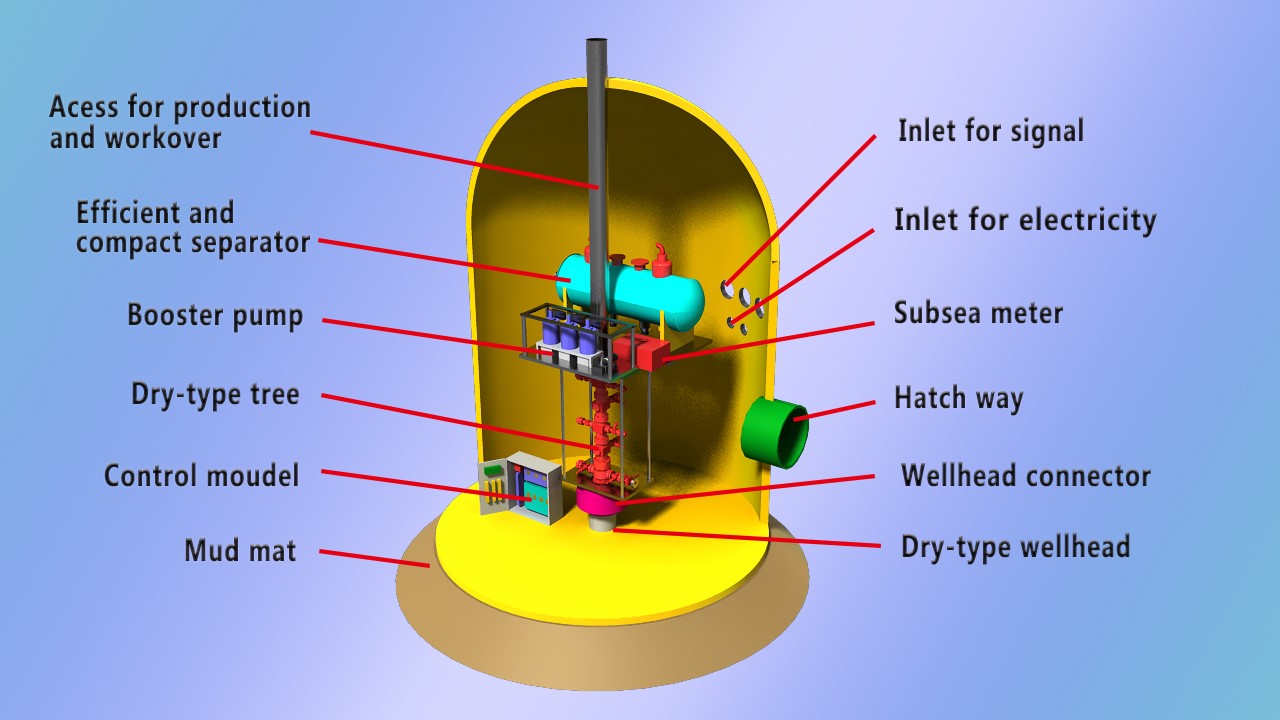

1) Integrating the horizontally distributed subsea facilities of the conventional SPS of wet production into a vertical compact layout of all subsea facilities spaced by a chamber (called subsea space, shown in Fig.1) or one more if necessary for dry production. There will be no need of connections of the wet facilities saving the investment on jumpers, PLET/PLEM, manifolds and their connectors, and accordingly on their installation, maintenance and repair, inspection and monitoring, decommissioning (IMRIMD), etc. The dry production facilities are 10 or even 100 times cheaper than the wet ones, and much easier for IMRIMD by which the reliability of the SPS is greatly improved. The great amount of investment on individual installation and decommissioning of each subsea wet facility is avoided by only once for the integrated subsea space.

2) Connecting the subsea spaces of the wells to a floated manifold by risers acting also as mooring lines, as shown in Fig.2. The manifold acts as only a connector of all risers for the spaces, and from which the export pipelines go to the land terminals or a FPSOs or other floating units. It is floated to a position of about 100m high over the sea bed rather than fixed to the bed by suction piles which are very expensive and hard to install. The floated manifold can also be a share of subsea spaces respectively for separating, boosting or injecting systems, and make it true that all the subsea processing equipment or facilities could be in dry production. Such a three-dimension distribution of SPS greatly simplifies the development scenario of a deepwater oil field, reducing the CAPEX of the field up to 50%.

3) Making it possible that hydrate or wax will never be blocking the flow of oil and gas in deepwater fields. A lot of money is spent on the flow assurance of subsea pipelines and production systems. Hot water cycling, electric heating and chemical injecting are three ways to prevent hydrate or wax from blocking the flow of oil and gas. The new concept for the SPS is to make a mixed flow of hydrate or wax together with oil, gas, sand and water, limiting the size of developed hydrate or wax. The solution is to find out the conditions of size limit of hydrate or wax for flow assurance and how to maintain such conditions. We’ll develop drying nano membrane to avoid hydrate, super-oleophobic nano membrane to avoid wax, and phase-change membrane to absorb heat from oil and release heat to control the temperature to a content of flow assurance. The thermo-physical engineering model of the inner coated nano phase-change materials and the thermodynamic prediction model for the nano phase change material inner laminated pipelines conveying multi-phase flow are the main theoretical investigations on the conditions of limit size of wax or hydrate for the mixed multiphase flow. The super-oleophobicity mechanism of nano membrane and its surface hydrophilicity are also basic problems for such a new concept of Never-Blocked Oil-Gas-Water-Sand-Hydrate-Wax Mixed Flow.

4) Application of smart technologies to the development of smart subsea production system and its IMRIMD. Smart manufacture will be widely applied to the industry. For the new generation SPS, smart materials will be developed together with corresponding smart sensors to monitor the change of environment, parameters of flow in the SPS and its structure state for the whole servicing life. Smart prediction of any structure damages or hazardous events will be made by smart monitoring, and self-healing of the structure will be possible to improve the safety and reliability of the SPS. Smart management for the whole life of SPS,by using of Big Data and Cloud Computing, will be performed for higher reliability.

The following fundamental research and engineering services detail the key methods and technologies for design, construction, testing, installation, monitoring, maintenance, repair and decommissioning for subsea pipelines/risers and subsea production systems.

l Dynamic analysis of ocean structures: theoretical investigation and numerical simulation by ABAQUS, ANSYS, SESAM, FLUENT, NASTRAN, SACS, AUTOPIPE, ORCAFLEX, etc. with special concerns on ice-induced vibration of installations, VIV of slender structures like deepwater risers and spanning pipelines in scouring, severe slugging induced dynamics of Risers, etc.

l Non-linear analysis of soil-structure interactions for structure dynamics: touch-down point details of the SCR fatigue, soil constraint on the global buckling of subsea pipelines, anchoring penetration with subsea pipelines by third-party activities, soil induced local buckling of suction piles, etc.

l Limit state analysis of ocean structures in extreme conditions: yielding, buckling, fatigue and fracture of beam, plate and shell structures, with special concerns on thermal global buckling/post-kuckling of subsea pipelines and combination with the local buckling/propogation with imperfection participation in HTHP conditions, collapse of deepwater shell/tube equipment by high pressure and thermal loads, ECA on damaged structures, configuration of deepwater riser systems, surface cracking of flexible composite pipelines, structure details of deepwater pipelines based on flow assurance and integrity management, etc.

l Installation analysis of subsea hardware and subsea pipelines/risers by applying hydrodynamics of multi-body system: parameter design for controlling the installation based on theoretical and numerical calculations, safety and integrity of the subsea pipelines/risers during installation in towing, S-lay, J-lay and R-lay, and integrity of suction structures being installed to seabed, etc.

l Inventive conceptual design of subsea production hardware, deepwater riser system, pipeline laying system.

l Safety and reliability of subsea production system including installation and decommissioning.

l Mathematical models for optimization of overall development program of offshore oil/gas fields and layout scenario of subsea production system.

l Integrity management of the ocean equipment and structures on the basis of risk based inspection and monitoring by using Big Data and Cloud Calculations.

l VR technology with application to underwater operations, emergency management and Big Data based decision-making information system, etc.

Fig.1 Subsea Space for Vertical Layout of Production Facilities in Deepwater

Fig.2 Development Scenario of a Deepwater Oil Field in Three-dimension Distribution of the New Generation SPS